In today’s fast-moving eCommerce landscape, businesses are constantly seeking ways to streamline their fulfillment operations. With fluctuating market demands and growing customer expectations, efficient logistics solutions are more important than ever. Among the most common services offered by third-party logistics (3PL) providers are kitting and assembly. Though often mentioned together, they serve different purposes within the supply chain.

Here’s a breakdown of what each service involves, how they differ, and how your business can benefit from choosing the right one.

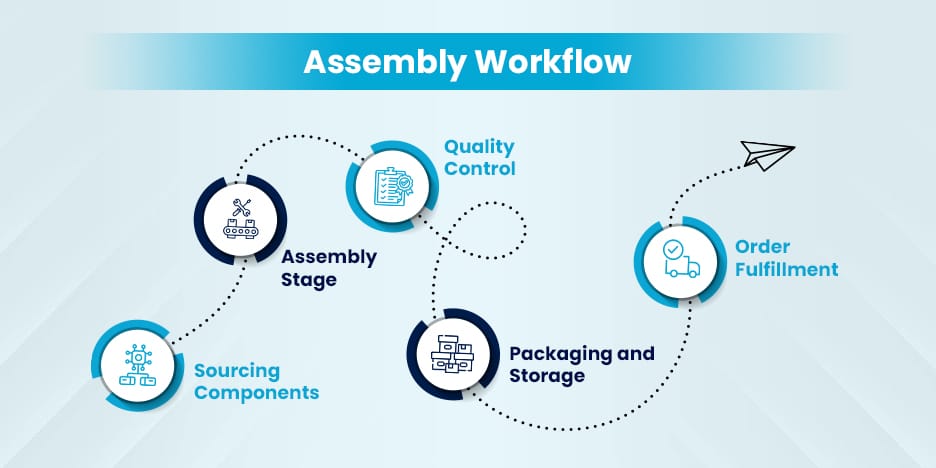

Assembly refers to the process of combining multiple components into a finished product that’s ready to ship. In many fulfillment centres, assembly is done on an assembly line, where each worker handles a specific part of the process. This increases efficiency and speeds up production—especially useful when large volumes of similar products are being prepared for shipment.

Sourcing Components: Items are sourced from multiple vendors or inventory locations.

Assembly Stage: All required parts are brought together to build a complete, sellable product.

Quality Control: Products are inspected to ensure they meet brand and quality standards.

Packaging and Storage: Finished goods are packaged, labeled, and stored as inventory.

Order Fulfillment: Once a customer places an order, the finished product is picked and shipped without delay.

Assembly is ideal for businesses producing high volumes of standardized products and looking to reduce lead times.

Kitting involves grouping multiple, related items together to create a ready-to-ship kit. These kits are often customized based on customer orders and assembled just before shipping. Unlike assembly, kitting does not involve manufacturing a new product but rather bundling existing items into a single package.

Examples include subscription boxes, promotional mailers, or DIY kits where end-users complete the assembly themselves.

Order Trigger: The process begins when a customer places an order requiring a kit.

Component Selection: Items are picked from inventory based on the kit specifications.

Kitting Stage: Products are grouped together according to the order.

Packaging & Shipping: The kit is packaged and shipped immediately, with minimal storage time.

Kitting is well-suited for businesses offering customizable, made-to-order products or bundled promotions.

Though both are essential to modern fulfillment operations, kitting and assembly differ in several key areas:

Assembly | Kitting | |

Inventory Strategy | Finished products are pre-built and stored, increasing storage costs. | Items stored separately and bundled after order, reducing overhead and avoiding overstocking. |

Customization & Flexibility | Less flexible; changes require production line adjustments. | Highly customizable; ideal for frequent product changes or personalization. |

Speed & Lead Time | Faster delivery—products are ready to ship. | Slightly longer processing time; better for custom orders. |

Cost & Scalability | More cost-effective at scale for standardized products. | Higher costs due to complexity but offers greater responsiveness to demand. |

Whether you need tailored kits or high-volume assembly services, both processes play a vital role in ensuring a smooth and responsive fulfillment experience. By understanding the differences, you can better align your operations with your business goals.

At PPFD, we provide expert kitting and assembly solutions tailored to Canadian eCommerce businesses. Our fulfillment professionals, technology-driven processes, and commitment to quality help you reduce costs, meet delivery timelines, and exceed customer expectations.

Reach out to us today to learn how we can support your fulfillment strategy with trusted, flexible, and scalable solutions.

Share :

get started

Our team is eager to partner with you and show why PPFD is the go-to choice for businesses aiming to streamline their logistics and distribution.