Behind every smooth-running supply chain, there’s a warehouse quietly doing its part. Automotive warehousing is the place where parts, tools, and materials are stored, tracked, and shipped with precision.

It’s more than just storage. It’s about timing, technology, and teamwork coming together to keep the industry moving without interruption. And because no two parts are alike, these warehouses have to be smart, flexible, and incredibly organized.

By the end of this blog, you’ll understand-

Automotive warehousing is basically the pause point in the supply chain. In this space, thousands of parts, components, and materials are stored and managed before they move to the next stage of production or delivery.

What makes it different from a regular warehouse is the diversity and detail of its inventory. Inside an automotive warehouse, you’ll find:

Managing all that variety isn’t just about storage; it’s about coordination and accuracy. Every piece needs to be tracked, protected, and moved at the right time to the right place.

That’s why these warehouses are designed for efficiency, safety, and precision. Most use:

In short, automotive warehousing is where organization meets motion. It’s the behind-the-scenes system that keeps the supply chain steady, helping manufacturers, suppliers, and distributors work in sync, so everything else runs on time.

So, why is warehousing so important in the automotive world? The answer lies in how interconnected and fast-paced this industry is. Every vehicle is made of thousands of parts, often sourced from multiple countries and suppliers.

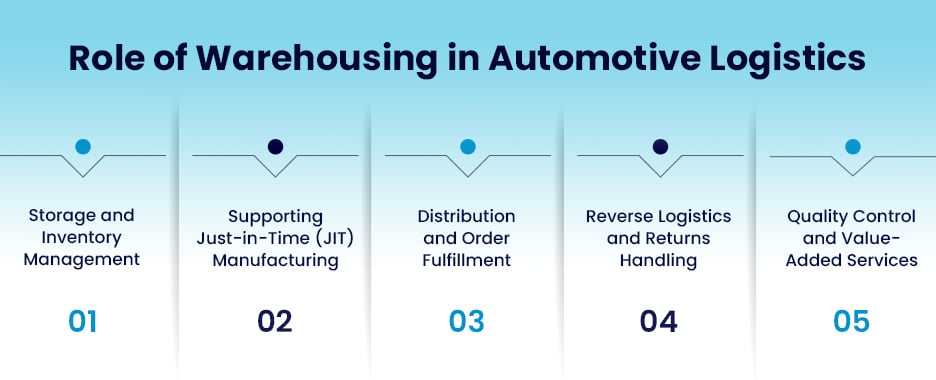

Without a well-organized warehousing system, the whole production process could easily grind to a halt. Let’s look at some key roles automotive warehouses play:

At its core, automotive warehousing is about storing parts, but there’s a lot more to it than meets the eye. These warehouses handle thousands of different items, from small sensors to heavy components, and each one needs to be stored carefully and correctly.

To keep things running smoothly, modern warehouses use smart inventory systems that track every item in real time, what’s in stock, where it’s placed, and when it’s needed.

This means that when a factory suddenly asks for brake pads or sensors, the warehouse team can find and deliver them right away, keeping production on track without any hold-ups.

The automotive industry follows a system called Just-in-Time, where parts and materials reach the factory exactly when they’re needed. Not too early and not too late.

Warehouses make this possible by acting as a middle point between suppliers and production lines. They hold extra stock just in case something gets delayed, so the factory doesn’t have to stop work.

In short, automotive warehouses help keep everything running on time. They make sure the right parts arrive at the right moment, keeping production smooth and steady.

Once parts are ready or vehicles are assembled, the warehouse takes on its next big job, getting everything where it needs to go.

This means preparing and shipping products to dealerships, retailers, or export centers on time and in perfect condition. Every shipment has to be packed properly, labelled correctly, and sent out according to strict delivery schedules.

To make it all happen smoothly, warehouses work closely with transport teams and use tools like real-time tracking and route planning. The goal is simple – make sure every order reaches the right place, on time, without any extra cost or confusion.

It’s not just about sending parts out; warehouses also manage the flow of goods coming back in.

This could include defective parts, surplus inventory, or recyclable materials. Handling returns efficiently helps companies recover costs, reuse materials, and reduce waste, all of which contribute to more sustainable and cost-effective operations.

Automotive warehouses aren’t just storage points; they often perform value-added services such as:

These additional steps help streamline downstream operations and improve overall supply chain accuracy.

Now, managing automotive warehousing sounds straightforward on paper, but in reality, it’s filled with complex challenges.

Let’s look at some of the most common hurdles and how companies are tackling them.

The automotive industry deals with a staggering range of components, like thousands of unique parts that vary in size, weight, and fragility. Storing them efficiently without mix-ups is no small task.

Solution:

Many warehouses now use automated storage and retrieval systems (ASRS) and barcode or RFID tracking. These tools improve accuracy, make inventory management faster, and reduce the risk of human error.

Automotive parts take up a lot of space, especially bulky items like body panels, tires, and engines. With rising real estate costs, making the most of every square foot is crucial.

Solution:

Modern warehouses use vertical racking systems, mezzanine floors, and dynamic shelving to maximize space. Smart layout planning based on product movement frequency (fast-moving vs. slow-moving items) also helps boost efficiency.

The automotive supply chain moves at lightning speed. Delays or inaccuracies in picking and dispatching can disrupt entire production lines.

Solution:

To keep up, warehouses rely on Warehouse Management Systems (WMS) that track inventory in real time. Some even use robots and AI-powered systems to handle repetitive tasks like picking, sorting, and packing.

Returned parts can quickly create chaos if not handled properly, especially when they need inspection, repair, or recycling.

Solution:

A structured reverse logistics process helps manage returns efficiently. Dedicated zones within warehouses are used for testing, refurbishing, or disposing of parts, keeping the main flow of operations unaffected.

From global chip shortages to transportation delays, supply chain disruptions can hit hard, and warehouses are often where the pressure shows up first.

Solution:

Building flexibility into warehousing operations is key. This includes maintaining safety stock, working with multiple suppliers, and using predictive analytics to forecast demand more accurately.

Finding skilled labour for warehouse operations, from forklift operators to inventory managers, can be tough.

Solution:

Warehouses are increasingly turning to automation, training programs, and even wearable tech that guides workers through processes step-by-step to improve efficiency and reduce dependency on specialized skills.

With growing focus on green logistics, automotive warehouses face pressure to reduce their environmental footprint.

Solution:

Many facilities are adopting eco-friendly practices, such as:

These not only help the planet but can also lower operating costs in the long run.

Automotive warehousing may not grab headlines, but it quietly keeps the whole industry running. Here’s why it matters:

As automation and sustainability grow, warehouses are becoming smarter and more efficient.

Looking for a reliable automotive warehousing partner?

PPFD, a well-known automotive warehouse company, offers end-to-end storage and logistics solutions to keep your operations moving seamlessly.

Share :

get started

Our team is eager to partner with you and show why PPFD is the go-to choice for businesses aiming to streamline their logistics and distribution.