If you’ve ever dealt with incorrect orders, frequent returns, or customers asking, “Where’s my package?” — the issue often starts inside the warehouse.

A pick & pack warehouse is designed to handle orders individually rather than in bulk, ensuring each item is accurately picked, packed, and shipped. For e-commerce businesses, this approach is essential for speed, accuracy, and customer satisfaction.

In this guide, we’ll cover:

Over the past decade, online shopping has grown at an unprecedented rate. Along with that growth has come higher customer expectations — faster delivery times, real-time tracking, and near-perfect accuracy.

Waiting weeks for an order is no longer acceptable. Same-day or next-day delivery is quickly becoming the norm, and pick & pack warehousing makes this possible.

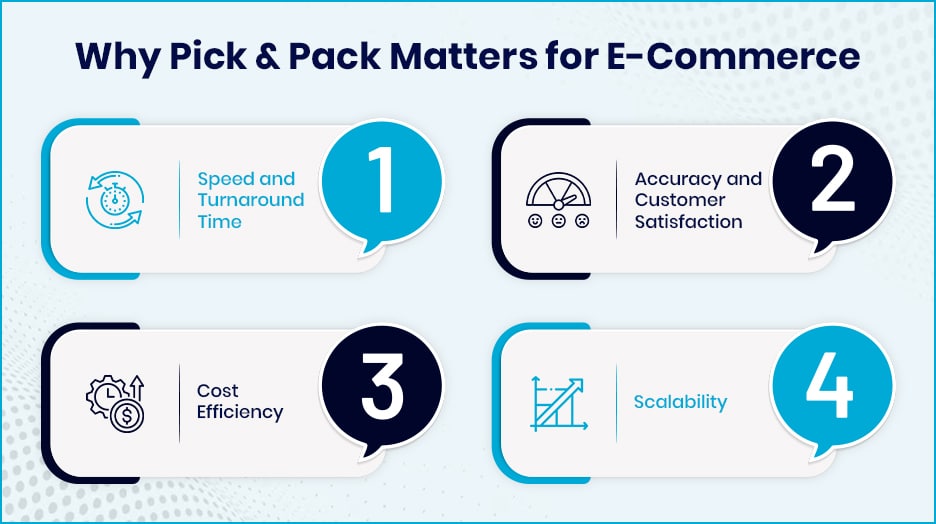

Pick & pack operations significantly reduce the time between when an order is placed and when it leaves the warehouse. With streamlined picking routes, organized inventory, and efficient packing stations, orders move quickly from shelf to shipment.

The result? Faster fulfillment and happier customers.

If you’re looking to learn more about third-party logistics, check out our guide: 3PL eCommerce Fulfillment: Benefits, Tips, and Common Mistakes to Avoid.

Few things frustrate customers more than receiving the wrong item. Strong pick & pack workflows reduce errors through barcode scanning, quality checks, and standardized packing procedures.

Accurate fulfillment leads to fewer returns, better reviews, and stronger customer loyalty — especially for businesses operating large warehousing and distribution networks.

Pick & pack warehousing helps businesses do more with less. By optimizing storage space, minimizing unnecessary handling, and reducing labor inefficiencies, companies can lower fulfillment costs.

Those savings can then be reinvested into marketing, product development, or growth initiatives.

Whether you’re shipping 50 orders per day or 5,000, an effective pick & pack system scales with your business. It provides the flexibility needed to manage seasonal spikes like Black Friday or holiday surges without disrupting operations.

Here’s a step-by-step look at how pick & pack fulfillment operates behind the scenes:

Once a customer places an order, it is automatically transmitted to the warehouse management system (WMS). Each order includes item details, quantities, and shipping instructions to ensure nothing is missed.

The system generates a pick list — a digital roadmap showing warehouse staff exactly what items to collect and where they’re located. Accurate pick lists are the backbone of efficient pick & pack operations.

Items are retrieved using different picking methods, depending on order volume and layout:

Picked items are sent to the packing station, where they are carefully packed, protected, labeled, and prepared for shipment. Proper packing reduces damage, returns, and customer complaints.

Before leaving the warehouse, orders are verified for accuracy and quality. Once approved, shipments are handed off to carriers and sent on their way.

Even with strong systems, errors can occur. Common causes include:

Misread labels, incorrect picks, or packing mistakes can happen — especially during high-volume periods.

Inaccurate inventory records can lead to stockouts, overselling, or incorrect substitutions.

Disorganized or cluttered layouts slow down picking and increase the risk of errors.

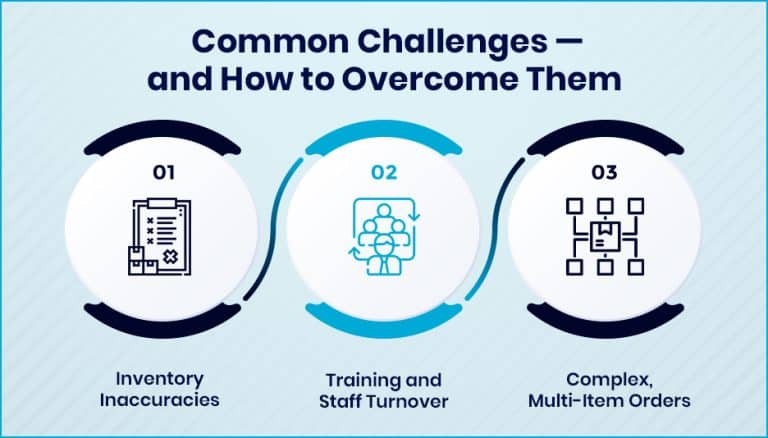

Pick & pack warehousing comes with challenges, but the right strategies can mitigate them:

Use real-time inventory tracking and regular cycle counts to maintain reliable data.

Strong onboarding programs and intuitive systems help new hires perform accurately and efficiently.

Organize inventory by product velocity and leverage batch or zone picking to improve speed and accuracy.

Pick & pack warehousing doesn’t have to be complicated. With the right processes in place, you can:

Whether you’re launching a new e-commerce brand or scaling an existing one, optimized fulfillment can be a major competitive advantage.

Looking for a partner to fine-tune your pick & pack operations? PPFD specializes in fast, accurate, and scalable fulfillment — so you can focus on growing your business instead of fixing fulfillment issues.

Not necessarily. Pick & pack can be very cost-effective, especially for businesses shipping multiple SKUs. Costs depend on order volume, packaging requirements, and automation levels.

Peak periods are managed by scaling labor, optimizing warehouse layouts, and leveraging automation — making it easier to handle increased demand without sacrificing accuracy.

Yes. Orders can be fulfilled locally and shipped globally using international carriers, allowing businesses to expand into new markets.

Pick & pack is ideal for e-commerce businesses with smaller, diverse orders that require fast, accurate fulfillment — especially those with fluctuating inventory levels or custom orders.

Share :

get started

Our team is eager to partner with you and show why PPFD is the go-to choice for businesses aiming to streamline their logistics and distribution.