You’ve probably wondered at least once:

How your favourite online store manages to deliver your order so quickly,

or

How supermarkets always seem to have just the right products on their shelves?

The secret behind this is effective warehouse management, keeping every business running smoothly. It’s the backbone of logistics that ensures products are stored, organized, and dispatched with precision.

So, are you a business owner, a supply chain enthusiast, or just curious, this guide will walk you through the world of WM. We’ll cover everything from the basics to advanced strategies, making it practical and relatable.

Your warehouse is just like a giant puzzle, where each piece, be it a box, pallet, or a barcode, needs to fit together perfectly to complete the picture. This is where warehouse management comes in. For us, it’s both an art and a science that ensures all those pieces come together seamlessly.

In a layman’s terms, it is the process of overseeing the day-to-day operations within a warehouse. Let’s take you through its key components –

This one is the starting point where the magic begins. It’s all about accepting and checking incoming goods to ensure everything is in order.

Once all the goods are received, a dedicated space is needed to store them. During this phase, the items are placed in the easy to access place. This saves a lot of time while finding the product when you actually need it.

This involves knowing exactly what’s in stock, where it is, and how much is available, keeping everything organized and accounted for.

Then comes picking and packing, which involves selecting items for orders and preparing them for shipment. It is a crucial step in fulfilling customer requests.

The grand finale! This step involves sending products out the door to customers or retailers, ensuring they arrive on time and in perfect condition.

Sometimes, things don’t go as planned. Handling products that come back is just as important as getting them out the door in the first place.

You must know that it is not only about moving boxes. It is more about using the space wisely, keeping errors to a minimum, and making sure customers get what they want. Not just what they want, but when they want.

Are you one of those who always think – “Isn’t warehouse management just a back-office thing?”. Yes? Then it’s time to clear that misconception. Because WM is the foundation of any business that deals with physical goods, especially in the areas of warehousing and distribution.

Let’s know why effective WM is the big deal –

How do you feel when you receive a wrong or a delayed package? Frustrated, isn’t it? This is why proper WM is crucial, as it ensures orders are accurate and delivered on time. With this, you are sure to gain happy and loyal customers.

Did you know? Insufficient warehouses bleed money, through wasted space, lost inventory, and extra labour. But a streamlined means lower costs and less waste. Think of it like organizing your kitchen pantry, when you know what all is available to use, you avoid buying duplicates and save money.

Knowing what you have (and where it is) prevents both overstocking and stockouts. This balance keeps cash flow healthy and shelves stocked just right. Imagine a well-organized inventory system where you can easily track your products—this not only saves time but also helps you make informed purchasing decisions.

Dreaming of growing your business? Solid warehouse management systems make it easier to scale up without chaos. As your business expands, a well-structured warehouse can adapt to increased demand, ensuring that your operations remain smooth and efficient. This means you can focus on growth rather than getting bogged down by logistical nightmares.

These days, with so many options out there, speed and accuracy really make all the difference. When your warehouse runs like a well-oiled machine, it gives you a serious edge. Customers are much more likely to stick with you when they know their orders will arrive quickly and exactly as promised.

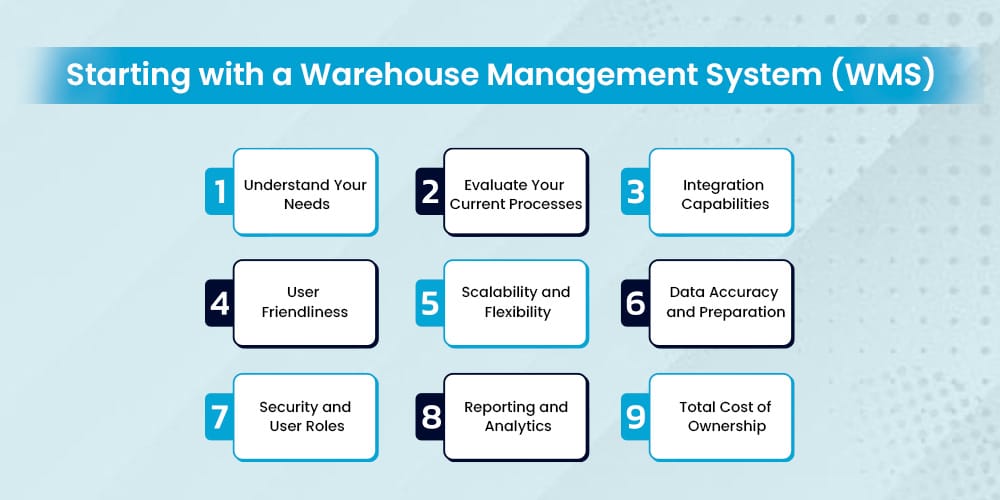

So, have you already decided to invest in a warehouse management system, that’s a smart decision! But before you move ahead, you need to keep a few things in mind, including –

Every warehouse is a little different, right? Are you juggling thousands of SKUs or just a handful? Do you need some fancy automation, or are you just looking for better tracking? Take a moment to jot down your must-haves and nice-to-haves. This will help you find the perfect fit!

You should take a small tour of your warehouse, it is going to help. Try to identify where things might be slowing down or where mistakes tend to pop up. Doing this will help you get a clearer picture of what features you should prioritize in your new WMS.

Your warehouse management system should go well with your other systems, like ERP, ecommerce platforms, or shipping software. Seamless integration is key as it saves you more time and helps in reducing errors.

A high-tech system is only as good as its usability. Look for something with an intuitive interface and solid training resources. Your team should feel comfortable using it, not overwhelmed!

Choose a system that can grow alongside your business. Can it handle more products, new sales channels, or even additional warehouses down the line? You want a solution that adapts to your needs as you expand.

Note – If you’re also working with third-party logistics providers (3PLs), it’s important your WMS integrates smoothly with theirs. For a deeper dive into mastering 3PL partnerships, check out our Smart Business Guide to Mastering Third-Party Logistics (3PL).

Before you make the switch, take some time to clean up your inventory data. Trust us when we say starting with accurate data will save you a ton of headaches later on! So, what else do you need?

It is crucial for a business owner to know who needs access to what. Protecting sensitive information is crucial, so make sure you set up user roles that ensure accountability and security.

They say “what gets measured gets managed”! And this is so true. You must ensure that your WMS offers the reports and dashboards you need to keep track of performance and make informed decisions.

You don’t have to only focus on the initial price tag, rather consider the full picture. Keep in mind the setup, training, maintenance, and any potential upgrades. Afterall, it’s all part of the investment!

So, are you all set to launch your new WMS or give your warehouse all new makeovers? Here is how you can guarantee a smooth and successful transition –

Know what success looks like for your team? Is it faster order processing, fewer picking errors, or improved inventory accuracy? Be clear with defining your objectives and convey them to everyone involved.

Change is not easily acceptable, the best you can do is to include your team from the beginning. You need to tell them about the perks of the new system, address their concerns, and encourage their input.

Before you roll out the complete system, start with a small area for testing it. When you do this, you can identify and side-by-side resolve issues. This even builds confidence in the new system .

No matter how advanced your system is, it can falter without proper training. So, it’s always a good idea to provide hands-on sessions, create user-friendly guides, and ensure ongoing support to help your team adapt smoothly.

Keep an eye on metrics like order accuracy, inventory turnover, and picking speed. Use this data to identify areas for improvement and celebrate your successes along the way.

Remember, no plan survives first contact with reality. Be prepared to adjust processes and strategies as you learn what works best for your team and operations.

Warehouse management is an ongoing journey, not a one-time project. Regularly review your processes, seek feedback from your team, and stay informed about industry trends to continuously enhance your operations.

While we’ve covered the big picture, here are a few more key points that can really make your warehouse stand out:

Safety First – A safe warehouse is a productive one! Make sure to invest in training, clear signage, and regular equipment maintenance to keep everyone safe and efficient.

Leverage Technology – Utilize the power of technology! Tools like barcode scanners and robotics can significantly enhance accuracy and efficiency in your operations.

Plan for Returns – Let’s face it—returns are just part of the game. Set up a straightforward and efficient process to handle them smoothly.

Sustainability Matters – Going green isn’t just good for the planet; it’s great for your brand too! Implement eco-friendly practices like recycling packaging and optimizing delivery routes to show your commitment to sustainability.

Warehouse management might not be the most glamorous part of your business, but it’s truly the heartbeat of any operation that deals with physical products. When you get it right, you’ll not only delight your customers but also empower your team and position your business for growth in a competitive landscape.

Keep in mind: every great delivery begins with a well-organized warehouse. Are you ready to transform yours? The journey starts now—one organized shelf, one happy customer, and one smart decision at a time.

Share :

get started

Our team is eager to partner with you and show why PPFD is the go-to choice for businesses aiming to streamline their logistics and distribution.