introduction

Container destuffing, or container unloading, is a vital logistics service involving the systematic unloading of cargo from shipping containers. This process is crucial for businesses that rely on international shipping, as it helps manage inventory, reduce lead times, and improve overall operational efficiency.

Effective container destuffing services enhance the flow of goods through the supply chain. By reducing unloading and processing times, businesses can better control inventory, minimize storage costs, and ensure timely delivery. At PPFD, we offer top-notch container destuffing services that streamline logistics operations, ensuring your products move seamlessly from port to warehouse to the final destination.

Container destuffing involves unloading goods from containers using specialized equipment for heavy or bulky items. The process includes verifying contents against shipping documents, inspecting for damage, and organizing goods for storage or distribution. Our experienced team ensures each step is performed with precision, maintaining the integrity and quality of your products.

Key Benefits and Applications

Quick unloading reduces transit time, speeding up the supply chain.

Efficient destuffing minimizes storage costs and labor expenses.

Accurate unloading updates inventory levels in real-time, enhancing control.

Suitable for various industries, from retail to manufacturing.

Quick unloading reduces transit time, speeding up the supply chain.

Efficient destuffing minimizes storage costs and labor expenses.

Accurate unloading updates inventory levels in real-time, enhancing control.

Suitable for various industries, from retail to manufacturing.

Services Offered

Unique Features and Advantages

Our container destuffing services maximize efficiency and accuracy, offering:

Trained professionals ensure safe and efficient handling of goods.

State-of-the-art machinery for handling various types of cargo.

Reduces unload time for floor-packed containers.

Ready to unload containers from around the world.

Trained professionals ensure safe and efficient handling of goods.

State-of-the-art machinery for handling various types of cargo.

Reduces unload time for floor-packed containers.

Ready to unload containers from around the world.

Technology and Equipment

Additional Benefits

Skilled professionals ensuring safe and efficient handling of parts.

State-of-the-art machinery for precise handling.

Industries We Serve

Examples of Industry Utilization

Plastic Pellets

Efficient unloading of 800 kg bags for manufacturing.

Building Supplies

Quick processing of insulation and other materials for construction.

Consumer Goods

Handling and processing of purses, bags, kitchenware, and knives.

Examples of Industry Utilization

Plastic Pellets

Efficient unloading of 800 kg bags for manufacturing.

Plastic Pellets

Efficient unloading of 800 kg bags for manufacturing.

Building Supplies

Quick processing of insulation and other materials for construction.

Unique Selling Points

Container destuffing is the process of systematically unloading cargo from shipping containers. It is essential for businesses relying on international shipping because it improves inventory control, reduces lead times, and enhances overall supply chain efficiency.

Efficient destuffing speeds up unloading and processing, helping businesses reduce storage costs, maintain accurate inventory levels, and ensure products move quickly from port to warehouse and then to their final destination.

The process includes unloading cargo using manual labor or specialized equipment, verifying goods against shipping documents, inspecting for damage, sorting items, and preparing them for storage or distribution—all performed with careful precision.

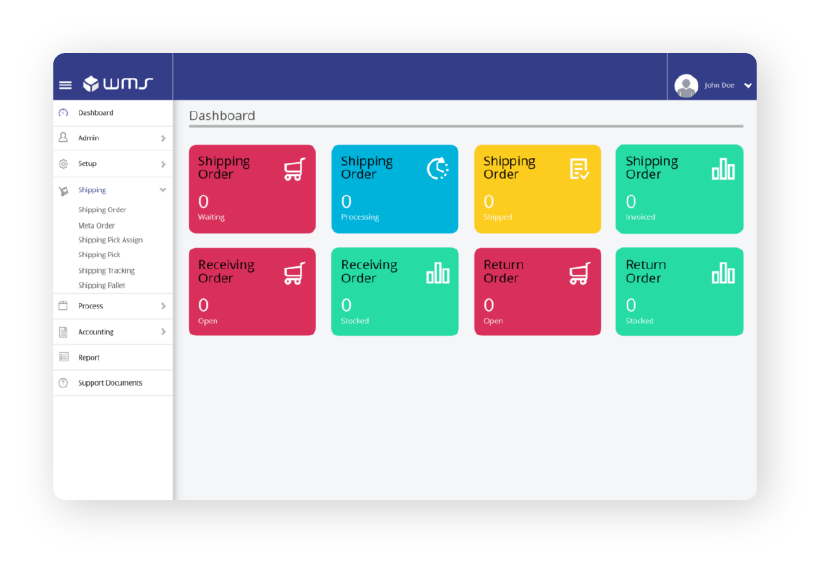

PPFD provides manual and automated unloading, damage inspection and reporting, sorting and palletizing, and real-time inventory updates through our Warehouse Management System (WMS).

We utilize forklifts, pallet jacks, automated systems, quality control scanning, and an expandable rolling conveyor belt for efficient unloading—supported by a robust WMS offering live inventory tracking and client dashboards.

Industries such as automotive, retail, construction, and manufacturing rely heavily on efficient destuffing to handle heavy parts, high-demand goods, building materials, raw materials, and consumer products.

get in touch

Contact PPFD today to schedule a consultation or request a customized quote tailored to your needs. Our team of experts is here to help you streamline your operations and achieve greater efficiency. Reach out to us now and experience the PPFD difference.